Automation

The automation of storage and production solutions helps increase production efficiency and reduce the costs of certain processes. Depending on the quantity of stored and processed materials as well as the complexity of the production or picking process, we offer simple, standard automation solutions but also we develop complex, customised systems.

We have integrated our automation systems with processing machines from many different brands such as Amada, BLM, Durma, Eagle, LVD, Mazak, Mitsubishi, Salvagnini, TCI and TRUMPF as well as global CAD/CAM software suppliers such as CADMAN, Lantek, Metalix or SigmaNEST.

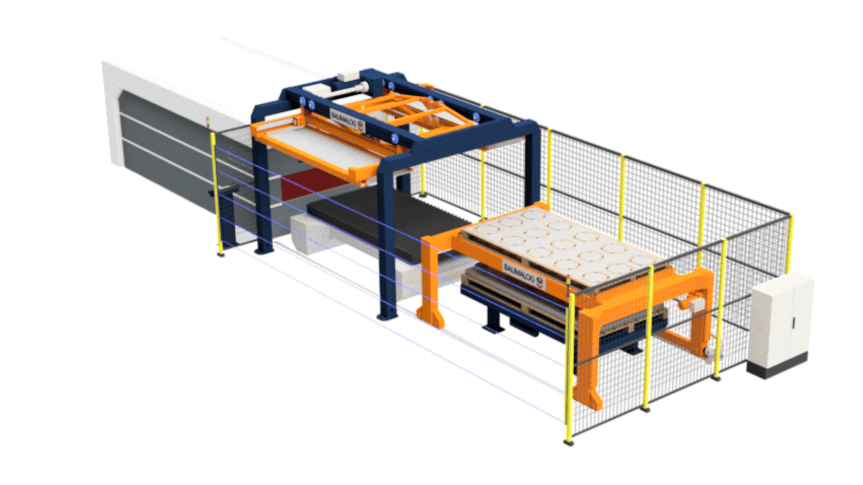

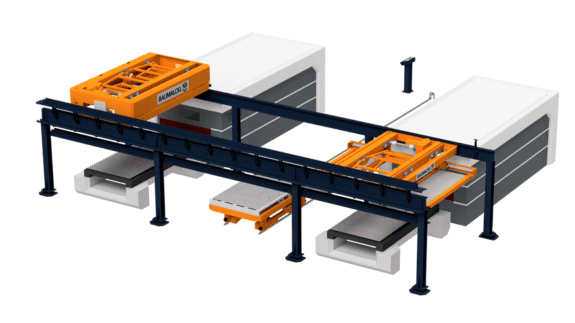

Loader with storage system

Automated loading and unloading module for laser cutting machine integrated with automated storage system

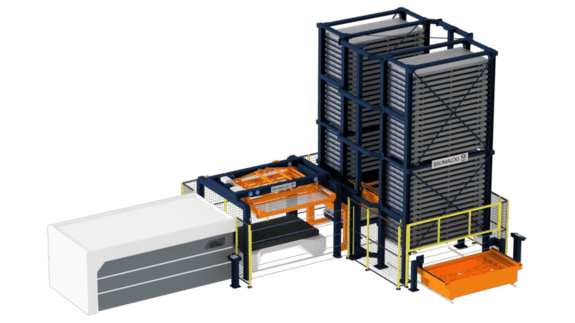

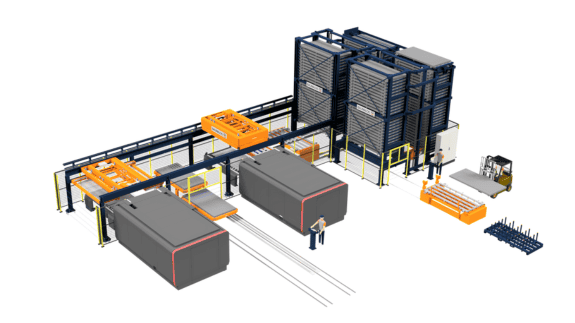

SmartFlow System

The combination of automated storage system with loading and unloading of one or more laser cutting machines and different access points for the cut-out parts.