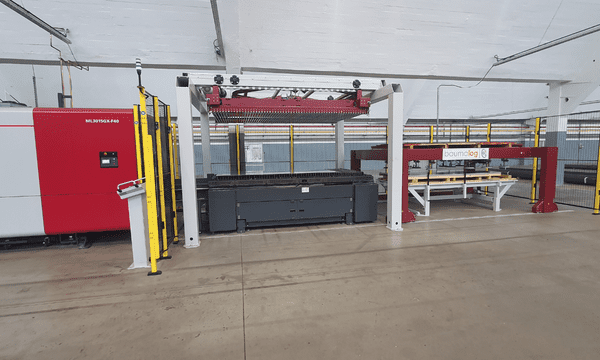

Loader – automated loading and unloading system for laser cutting machines

Loader is an automated system that is designed to load the steel sheets onto the laser cutting machines table and unload the cut pieces from the laser cutting table. The system can be integrated with laser cutting machines of various brands. The major elements of the system are two separately working modules – loading and unloading.

The loading module is equipped in a set of vacuum suction cups, a dedicated steel sheet separation system and a steel sheet thickness measure system. The loading module transports the steel sheets onto the laser cutting machine table. The unloading module consists of a two-element forks, which unload the cut pieces from the laser cutting table onto a pallet or shelf. The time of the whole cycle does not exceed 75 seconds.

The construction of the Loader enables to load the steel sheet directly onto the laser cutting machine table – manually or by use of a forklift. To use the full possibilities of the laser cutting machine it can be integrated with a automated storage system for steel sheets what increases the efficiency of steel sheet processing and enables the access to many types of steel sheets and additionally enables the storing of cut pieces inside the system.

Advantages

- increased efficiency of the laser cutting machines

- minimization of laser cutting machine downtime

- automated transport of steel sheets and cut pieces

- fast access to the material in case of integration with the automated storage system

- increased work safety

- limited forklift use

Features of the Loader system

- possibility of processing sheets 3 m x 1.5 m, 4 m x 2 m, 6 m x 2 m

- possibility of integration with laser cutting machines from different manufacturers

- the loading and unloading processes are executed independently

- the shelf or pallet with the raw material is placed on a unmovable frame

- the shelf for the cut pieces is placed on a movable frame

- the compact size of the system doesn’t need much space

- possibility to equip the unloading module with the system to prevent sheets from scratching

- sheet thickness control and sheet separation system

- modular construction allows to extend the system in the future

- possibility of installing different specification stations (movable, solid, buffer)

- possibility of connecting a few laser cutting machines in a line configuration (MultiLoader)

- short material change time

- the construction of the Loader does not limit the access to the laser cutting machine table

- intuitive and easy to control software by Baumalog

Technical data

| Type | Loader 3015 | Loader 4020 | Loader 6020 |

| Max. sheet dimension | 3 m x 1.5 m | 4 m x 2 m | 6 m x 2 m |

| Max. sheet weight | 900 kg | 1600 kg | 2300 kg |

| Max. sheet thickness | 25 mm | 25 mm | 25 mm |

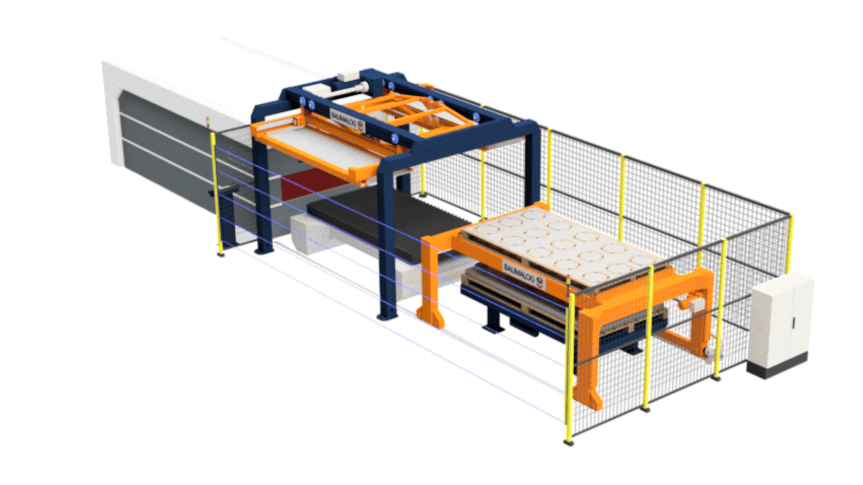

Operating principles

The animation shows: taking a sheet from the pallet using the loading module – thickness control and confirmation of picking only one sheet – delivering the sheet to the laser cutting machine table – the unloading module takes the cut parts and puts them on the pallet.