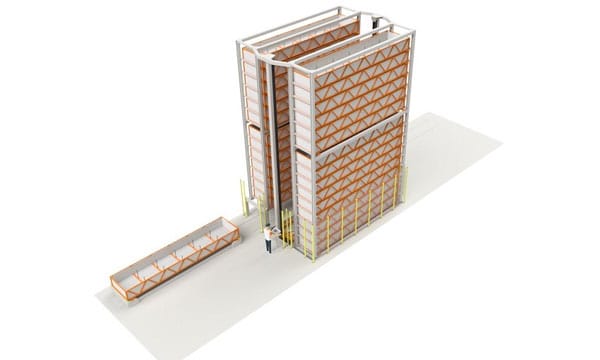

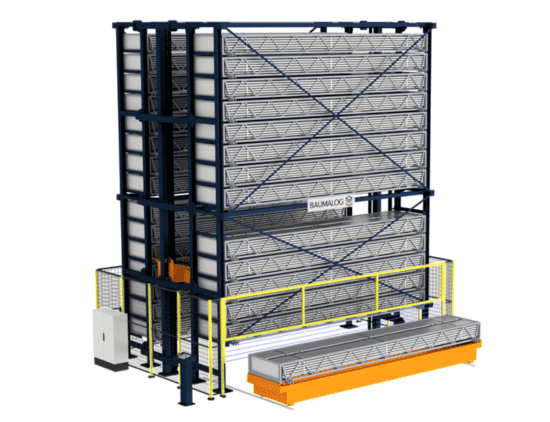

TwinTower® automated storage system

Advantages

- storage space saving even to 85%

- easy and quick access to stored goods

- shorter warehouse operation time

- easy loading/unloading of goods

- intuitive controlling software

- integration with other manufacturing machines

- control over warehouse and manufacturing operations possible thanks to integration with ERP/WMS systems

- increased work safety

Features of the TwinTower® system

- max. length of stored goods – 12 m

- max. shelf load capacity – 5 000 kg

- max. system height – 20 m

- possible use of different height of shelves

- possible separation of goods inside of the shelf by using pins

- possible fullfilling of the bottom of the shelf

- loading-unloading stations can be placed on different levels of the building

- optional hydraulic lifting device that can be used for lifting profiles bundles

- 3 types of loading-unloading stations are available

- optional stations that drive outside the building

- possible outdoor installation

- loading and unloading of goods can be done by forklift, jib crane or manually

- Baumalog controlling software (possible integration with ERP and WMS systems)

Principle of operation

Presented TwinTower® system is equipped with a loading-unloading station that moves along the shorter side of the shelf. The animation shows: delivery of new profiles – transport of the goods to the storage column – transport of a shelf loaded with goods.

The TwinTower® for storing long items can be equipped with loading-unloading stations moving in different directions. The station can handle the loading of new items outside the building and deliver the goods close to the production machines inside the warehouse. The animation shows: delivery of new profiles outside the building using the station moving on the longer side of the shelf – moving the station under the storage column and transporting the shelf to the storage column – picking up and bringing the shelf with items to the station moving on the shorter side of the shelf.

The loading-unloading stations of our automated long goods storage systems can be equipped with a hydraulic lifting device that enables lifting long items and easy retrieval with a forklift without the need to use belts.