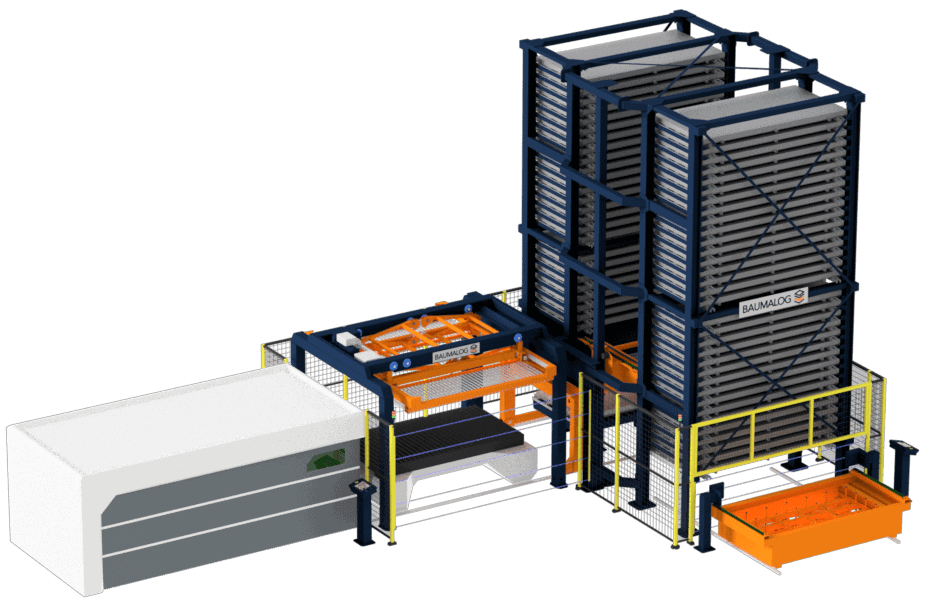

Loader with storage system

Automated loading-unloading system integrated with steel sheet storage system enables the automated loading and unloading of the laser cutting machine what significantly increases efficiency of work, enabling at the same time the fast and safe access to multiple kinds of sheets and storing the cut pieces inside the system. The construction of the system allows in case it is needed the access to the table of the laser cutting machine for the operators.

Advantages

- increase in productivity of the laser cutting machine

- systematizing the material flow in the cutting process

- automated steel sheet processing

- full use of the cutting speed of the laser cutting machines

- elimination of downtimes in the manufacturing process

- control over warehouse-manufacturing processes thanks to the integration with ERP/WMS systems

- increased work safety

- limited forklift use

Features of the Loader with storage system

- possibility of processing steel sheets of the dimensions 3 m x 1,5 m, 4 m x 2 m, 6 m x 2 m

- possibility of integration with laser cutting machines of various brands

- depending on the clients needs possible integration with MonoTower®, TwinTower® or TransferTower automated storage system

- short time of material change

- independend loading and unloading module

- possibility of connecting loading-unloading stations of different specifics (solid stations or movable stations, buffor stations)

- controlling software by Baumalog (integration with ERP/WMS)

Technical data

| Max. sheet dimension | 3 m x 1.5 m | 4 m x 2 m | 6 m x 2 m |

| Max. sheet weight | 900 kg | 1600 kg | 2300 kg |

| Max. sheet thickness | 25 mm | 25 mm | 25 mm |

Principle of operation

- Transport of the empty shelf from the storage column to the loading-unloading station

- Delivery of new sheets by forklift including depalletisation

- Return of the shelf with sheets to the storage column

- Delivery of another shelf with sheets to the loading module of the Loader system

- Sheet picking with thickness check

- Loading of the sheet onto the laser cutting table

- Moving the loading module to pick up the next sheet

- Cutting of the pieces in the laser cutting machine, their picking by the unloading module while the loading module picks a new sheet

- Removal of the cut pieces from the cutting table and depositing them on the shelf while loading the cutting table with a new sheet

- Transport the shelf with the cut-outs to the loading-unloading station