Automatic storage system for steel profiles

Client

Invest-Rem is a Polish company with over 30 years of experience in steel processing. The company has modern technologies enabling the prefabrication of sheet metal and profiles in the field of laser cutting, punching, bending, welding and painting, as well as mechanical and electrical assembly of manufactured components.

Challenges

- Reduction of the time of warehouse operations.

- Separation of the goods receipt area and the release of raw materials for further processing.

- Use of the available hall height.

- Reducing the use of forklifts in the production process.

Provided solution

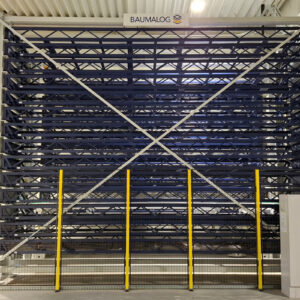

TwinTower® automated storage system for storing and transporting profiles, enabling the storage of over 80 tons of long materials up to 6 m long.

Storage system is equipped with 27 movable shelves, each with a load capacity of 3,000 kg. Loading and unloading is carried out by a mobile station moving on the track built into the floor. The station has the option of exiting on both sides of the storage column.

Warehouse management is carried out through Smart WMS Advanced software with 2 operator panels, ensuring full control over stock levels.

Results

- Reduction of access time to each assortment to just 3 minutes.

- Improving the transport of materials between the warehouse and production zones.

- Optimisation of warehouse space.

- The availability of the forklift does not affect the continuity of the production process.

- Digitalization information flow.

Technical data

| Parameter | Value |

|---|---|

| System height | 5 650 [mm] |

| Shelf lenght/width | 6 200 / 850 [mm] |

| Shelf capacity | 3 000 [kg] |

| Number of shelves | 27 [pcs] |

| Total capacity | 81 000[kg] |

| System lenght/width | 7 700 / 5 050 [mm] |