Automation of the bar and roll warehouse

Client

Orion Sp. z o.o. is a Polish company that is a distributor of technically advanced power transmission and internal transport products, pneumatics, hydraulics and other components for maintenance. Due to the continuous improvement of the quality of services provided, the company decided to organize and improve the steel processing process by using an automatic storage system for storing bars and rollers.

Challenges

- Increasing the efficiency of the process of cutting profiles and rollers.

- Facilitate access to a wide range of materials.

- Minimizing the use of forklifts in the internal transport process.

- Improvement of the process of loading raw material onto the saw feeder.

Provided solution

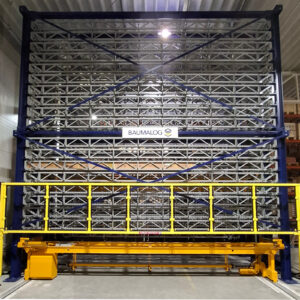

TwinTower® automatic storage system allows to store almost 80 tons of long materials up to 6 m long.

The rack is equipped with 38 movable shelves with a load capacity of 2,000 kg each. To make it easier for the operator to retrieve material from the warehouse, the short sides of the shelves are left open. Loading and unloading of the stored material takes place through a mobile station moving on a track built into the floor.

The system is operated and database managed using Smart WMS Standard software.

Results

- Shortening the time of loading raw material onto the saw feeder.

- Quick access to the stored assortment in less than 3 minutes.

- Optimisation of warehouse space.

- Reducing the share of forklifts in the production process to a minimum.

Technical data

| Parameter | Value |

|---|---|

| System height | 6 900 [mm] |

| Shelf lenght/width | 6 200 / 760 [mm] |

| Shelf capacity | 2 000 [kg] |

| Number of shelves | 38 [pcs] |

| Total capacity | 76 000 [kg] |

| System lenght/width | 7 700 / 4 300 [mm] |