Start of the biggest project in BAUMALOG’s history – Part 1 Automation

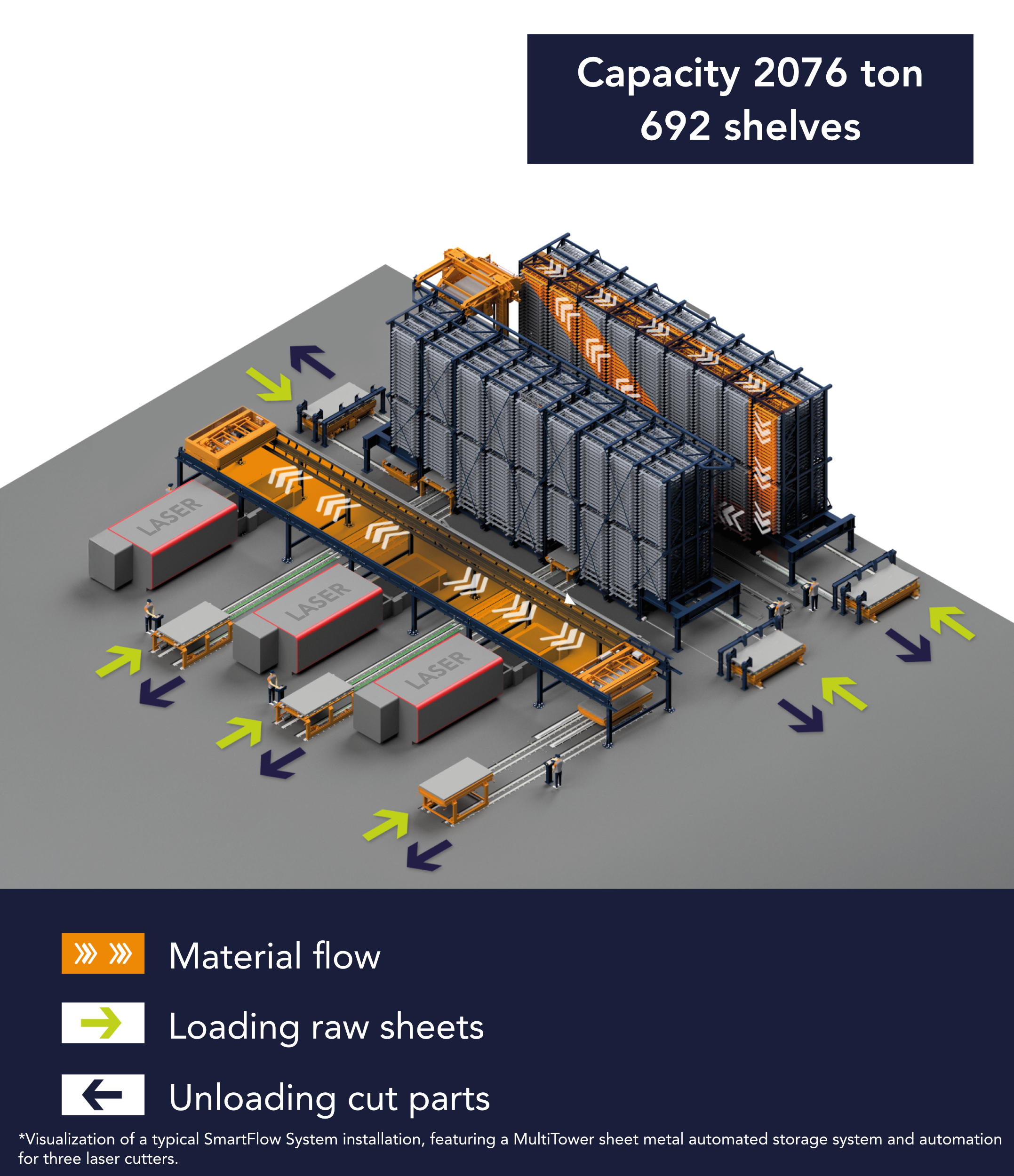

We’ve begun implementing our largest project to date: the SmartFlow System for Metaltech-Piasecki in Ciechanów.

This project includes:

- IT integration of ERP, APS (Advance Planning and Scheduling), and CAD/CAM systems, along with laser cutting machine interfaces, all connected to our WMS (Warehouse Management System). This allows for effective and efficient order planning and scheduling.

- Automation of loading and unloading for three laser cutting machines (one is a Mitsubishi, the others are still being selected).

- An automatic sheet metal warehouse with a capacity exceeding 2,000 tons (692 shelves, each with a 3-ton load capacity).

The goals of this project are to:

- increase the flexibility of the production process, enabling the fulfillment of High-Mix, Low-Volume orders.

- multiply the efficiency of sheet metal cutting (up to 864 tons per day).

- reduce the number of personnel required for the cutting process.

- eliminate forklifts from the sheet metal transport process.

The Metaltech project is a prime example of the digitization and automation of sheet metal processing, fully aligning with the principles of the 4th Industrial Revolution. By integrating multiple machines and IT systems, it will be possible to respond instantly to market demands and operate 24/7/365 without the constant presence of operators, ultimately multiplying production output.