One of our biggest automation system is underway!

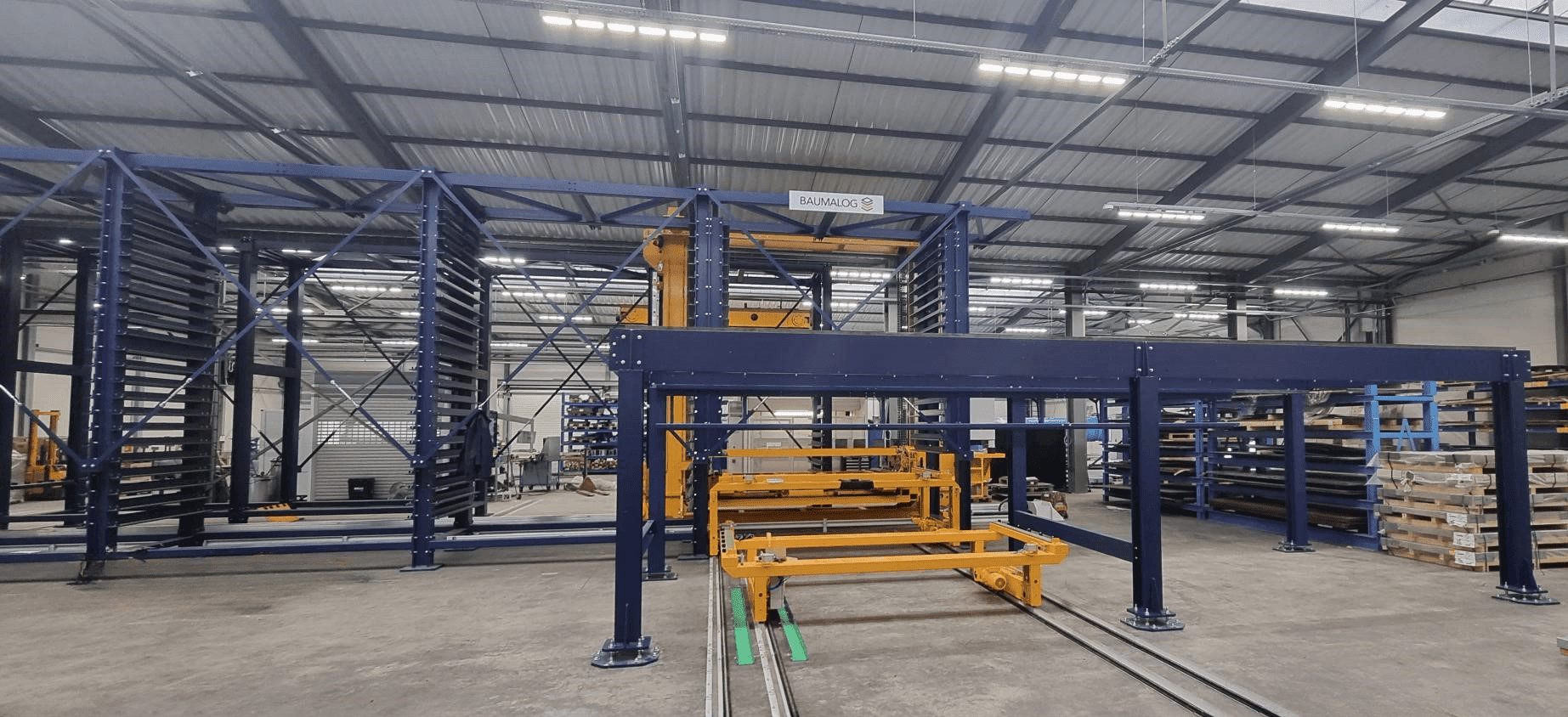

We have started the installation of one of our company’s largest projects. We are implementing a 29-metre-long SmartFlow System that automates sheet metal storage and intralogistic processes at NETECS company – a leading Polish manufacturer of industrial fans that continuously invests in new technologies to improve production efficiency and quality.

SmartFlow System at Netecs company – system components

The basis for the automation of sheet metal processing is the automated storage system MultiTower with a stacker crane, which can store up to 249 shelves with a load capacity of 3,000 kg each, giving a total capacity of 747,000 kg in 12 storage columns. The initial number of shelves installed will be 130 units with a total capacity of 390,000 kg, with the possibility of adding other shelves depending on the customer’s needs. The system will fully automate one laser cutting machine and support the operation of a second laser cutting machine and improve the flow of cut parts into the bending area.

Automation module and further expandability

The material flow to the laser cutting machine is made possible by the MultiLoader automation module, which is responsible for picking up the raw sheet metal from the shelf supplied by the two-level duo station and transporting it to the TRUMPF laser cutting machine table.. The cut-out details will be transported back to the storage system or outside the loading and unloading area, from where they can be directly picked up by the operator.

The second laser cutting machine, which is also located alongside the MultiTower, will also benefit from the proximity of the automated storage system. One of the access points will deliver material to the laser cutting machine area, making loading much easier. Depending on the customer’s needs, the structure will be prepared to upgrade the access station to a duo version, giving the possibility of installing a second MultiLoader automation system.

Multiplicity of access points

The system will be equipped with four access points moving along the short side of the storage system to improve material flow and operator handling:

- Loading station of the automated storage system with a depalletizer for separating sheet metal packages from pallets

- Storage system unloading station on the opposite side from the laser cutting machine

- Station with stop below the MultiLoader and in a separate sorting area for cut-out details

- Access station with stop by the a second laser cutting machine (expandable)

Smart WMS Advanced software

The Smart WMS Advanced software, is an integral part of the entire system. Developed by our specialists, Smart WMS enables data to be used to optimise production and storage processes. The Smart WMS Advanced module allows, for example, the management of articles through integration with ERP or WMS systems, the management of orders or the reporting the data. The job of operators is facilitated by 5 operator desks located in different areas of the storage system.

The next stages of the implementation and its results are ahead of us. Follow us on Linkedin and stay up to date!

Follow us on Linkedin!