Automation of the production process

Client

The Expo-Drew company (Poland) has been operating in the metal processing industry for many years. The company’s products are used for further production of elements for small urban, home and garden architecture, or e.g. fences and metal gazebos as well as ceramic tile displays. A wide range of offered products and services created the need to develop a machine park but also plan the flow of material in the production hall.

Features

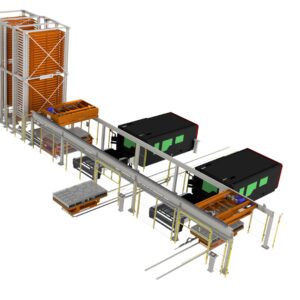

The design of the system was preceded by an analysis of the number of processed sheets, production stages, operated machines, production plans for the future and the possibilities offered by the production hall building. The implemented SmartFlow System takes part in several stages – from the delivery of raw material, through storage and transport, to production management. The system consists of:

- TwinTower automated storage system for metal sheets with a maximum size of 3 x 1.5 m,

- MultiLoader system for picking metal sheets from the rack, operating laser cutting machines and delivering cut elements to semi-automated access points,

- Production management software

The complexity of the implemented system allows for various material flow scenarios, e.g. delivery of cut elements from the laser to the sorting zone, but also return of elements to the automated storage system. The TwinTower storage system is equipped with 66 locations for storing shelves. Material loading is carried out through a semi-automated loading and unloading station, which is also used to separate sheet metal stacks from pallets.

Sheets stored in the storage system are transferred to the duo station, from where they are taken to the tables of laser cutting machines. The two levels of the duo station ensure high material availability for processing and no downtimes. The material collected by the loading module, equipped with a set of vacuum suction cups, is delivered to the tables of two laser cutting machines. Receipt of the cut details from the tables is carried out by the unloading module, equipped with two-piece forks, which puts the collected elements to the transport station (in order to deliver them to operators) or to the shelf of the automated storage system (at the duo station). The loading and unloading modules operate independently of each other, which is a factor increasing efficiency, as are the two levels of the duo station – while one delivers raw sheet from the rack, the other can return with finished elements for storage. Two semi-automated access stations are used to collect the elements cut by the operator – each of them is equipped with 2 steel pallets and placed on a specially built track, thanks to which the stations can move outside the working area of the system. The total length of the installed SmartFlow System is 26.6 meters, while the height of the TwinTower is 8.5 meters.

The system at Expo-Drew was equipped with the Smart WMS Standard software. Device integration allows for simple control of picking orders and material flow. The system also enables simple inventory management, full or semi-automated cooperation with laser cutting machines, ongoing reporting of inventory, demand for material and much more. The system is operated by means of 4 operator panel located in different parts of the system in order to facilitate the process control as much as possible.

In the production hall, we have also implemented the TransferTower automated storage system for profiles, which is responsible for storing and transporting long materials to the lasers. Both systems allowed, in a very small space, to organize the processing of pipes and sheets, and every element related to production has been thought out, which ensures comfort of use and high efficiency.

Technical data

| Parameter | Value |

|---|---|

| System height | 8 500 [mm] |

| Shelf lenght/width | 3 100/1 600 [mm] |

| Shelf capacity | 3 000 [kg] |

| Number of shelves | 66 |

| Total capacity | 210 000 [kg] |

| System lenght/width | 26 600/4 600 [mm] |

Media

Below we present short videos of the system operation and time-lapse of the assembly:

Want to find out how our solutions can help your business? Contact us. Our specialists will be pleased to answer any questions you have.