Modula vertical lift module

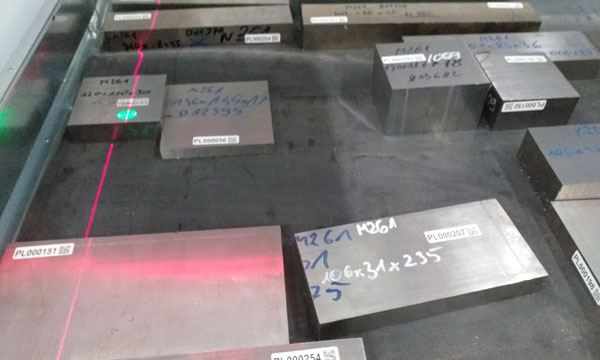

Modula is a perfect solution for storing different types of tools, components or spare parts in different industries. Goods are stored in a safe place, what ensures that the items don’t get damaged, with a additional option of limiting access for chosen operators. Multiple configuration options of the machine allow to strictly customize the machine to the company needs and optimalize the use of storage space. The goods stored inside the system are transported directly to the access bay due to what operators don’t have to waste time on looking for goods inside the warehouse. Additionally the Modula WMS software ensures easy operating of the storage system and inventory management, and multiple accessories help to avoid mistakes during the picking process.

Advantages

- saving storage space even to 90 %

- error-free picking due to multiple supporting accessories

- warehouse operation optimalization

- picking process optiomalization

- easy stocktaking

- use of the height of the building

- control of the inventory stock thanks to integration with ERP and WMS systems

- increased work safety

Features of the Modula automated storage lift

- max. height of the system – 16.1 m

- max. tray payload – 990 kg

- tray width from 1.3 m to 4.1 m

- possible use of trays with different payloads

- possible use of tray walls and partitions for full use of tray

- automated goods height control allows to thicken the placement of the trays inside the system

- option of double system of transporting trays is used to shorter the transporting time of the material

- internal or external acces bays

- picking bay is placed on a ergonomic height

- possibiltie to place the picking bay on both sides of the machine and on different levels of the machine

- possible outdoor installation

- intuitive operators panel

- a few kinds of Modula WMS software that allows to inventory management

Operating principles

Modula vertical lift module consists of 2 storage columns, between which the elevator moves that is responsible for the tray transport from the storage column to the picking bay. The fast move of the elevator enables to transport the goods fast to the operators.

The presented in the animation double tray transporting system ensures high effciency and enables processing more orders due to transporting the next tray a few secundes after picking of the goods.