Sheet metal flow automation

Client

Lazam CZ s.r.o. has been operating on the market for over thirty years and deals with comprehensive locksmith production, laser cutting of material, bending of sheets and bars, and surface treatment of finished products. Processing of raw steel elements is used to produce many products – on their basis, steel structures, gates, pallets for transporting heavy machines and many others products are created.

Features

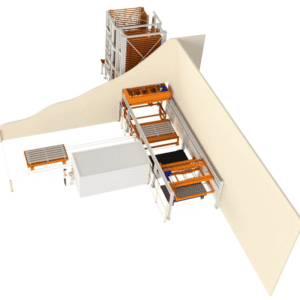

In order to optimize the production and material flow, we have implemented the SmartFlow System, which allows to use the full capabilities of the LVD laser cutting machine, integrating it with an automated storage system and loading and unloading modules. The implemantation of an automated system made it possible to reduce the working hours of operators while introducing night production.

The main elements of the SmartFlow System at Lazam are:

- TwinTower automated storage system with 66 shelves for storing 3 x 1.5 m metal sheets

- MultiLoader system for picking sheet metal from the storage system, operating laser cutting machine and delivering cut elements to semi-automated access points

- Smart WMS Advanced software for production control

The system is equipped with several access points that optimize the flow of material to the laser cutting machine and the collection of finished elements and their sorting for the next phase of production. The TwinTower storage system loading station is equipped with a depalletizer and goes outside the production hall to facilitate the material loading process. Between the storage and transport system there is a duo station which is responsible for quick and effective delivery of sheet metal for further transport to laser cutting machine.

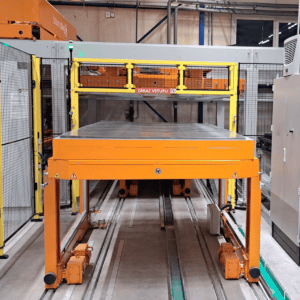

The MultiLoader transport system has several functions. Sheets can be loaded onto the laser cutting machine from the duo station connected to the storage system or from the other two points – the access station or the table – to which the cut elements can be deposited. Additional utility is the use of special spacers that the MultiLoader can transport from the table to the access point to separate the cut pieces by type.

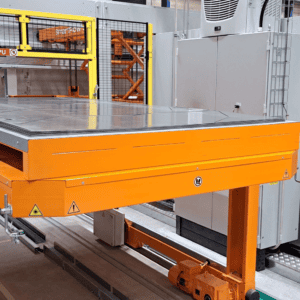

Access points are an important part of the system and enable the delivery of raw sheets from different points. The table located at the end of the technological line has an operational function – it allows loading raw metal sheets for processing or spacers, but it can also be a place to put cut details, which can be taken from there to the next stage of production. The double automated access station between the storage system and the laser cutting machine is equipped with 4 steel pallets. It can be used both to collect details cut by the operator, as well as to load raw metal sheets with a forklift. The double access station is located on the track, thanks to which it can move outside the working area of the system, facilitating its loading and unloading.

The element which integrate the entire production system is the Smart WMS Advanced software, which allows for ongoing monitoring and management of the production and storage process. The control can be carried out from the operator panel or from the application installed on the computer. Smart WMS Advanced additionally enables the management of articles through integration with ERP and WMS class production systems, reporting on stock levels and material location as well as order management. Optimization of the material flow by the SmartFlow System in Lazam company allowed to reduce production costs while increasing efficiency by fully using the possibilities of the laser cutting machine.

Technical data

| Parameter | Value |

|---|---|

| System height | 7 950 [mm] |

| Shelf lenght/width | 3 100/1560 (alternatively 1600) [mm] |

| Shelf capacity | 3 000 [kg] |

| Number of shelves | 66 |

| Total capacity | 198 000 [kg] |

| System lenght/width | 18 950/4 700 [mm] |

Media

Below we present a video of the operation of the SmartFlow System in Lazam:

Want to find out how our solutions can help your business? Contact us. Our specialists will be pleased to answer any questions you have.