Industry 4.0 – what is it and how do we understand it? Highlights of the fourth industrial revolution

Industry 4.0 is a term referring to the fourth industrial revolution, which began with the start of the 21st century. From this point on, digital solutions began to enter the production halls, extending the possibilities of simple automation. Despite the fact that the fourth industrial revolution has been going on for a good few years, it is still in its early stages. At present, many people working in the industry may not know what Industry 4.0 is and how the term can be understood practically. In the following article, we explain what Industry 4.0 is and how we see it in our company.

What is Industry 4.0?

Industry 4.0 is the popular name for the fourth industrial revolution – a new phase of industrial development that uses advanced digital technologies combined with automation to transform production processes to be more autonomous and efficient. The main features of Industry 4.0 are:

- The merging of the physical and virtual realms of production

- The use of Artificial Intelligence and Machine Learning

- Integration of machines and production processes through digital technologies and the internet (IoT)

- Human-machine interaction (HMI – Human-Machine Interface – technologies)

- Data analysis (Big Data)

These are just some of the features that can describe Industry 4.0, which will certainly evolve further in the years to come, developing with further technologies and application possibilities. Today, there is also a growing number of companies that are choosing to implement digital solutions into their production areas.

The fourth industrial revolution – key technologies

When discussing Industry 4.0, it is impossible not to mention a few key technologies, the application of which can be seen more and more frequently. We are also innovating with our products to digitise a significant part of production in manufacturing companies and beyond. These technologies are key to build a competitive advantage in the changing environment that many companies are currently facing.

Integrating machines and systems within a company

The concept of the Internet of Things (IoT) as a digital network of interconnected objects integrating with the physical world has been around for more than 20 years, although its practical application on a wider scale can only be seen more recently. In industry, where an entire fleet of machines operates on a single shop floor, networking helps to integrate the various machines, enabling diagnostics, safety monitoring or processes between them.

With Smart WMS software, it is possible to connect to a third-party ERP, WMS or machining machine software. Integration with other software is not an obstacle and does not reduce the quality of the process, but allows full and efficient exchange of information between machines and the possibility to view the production data of the connected machines.

Process visualisation on a computer screen

The production process is often highly complex and takes place over a large area. By viewing it on an industrial computer or operator panel, we can see the various stages and analyse production data from the different phases of production in one place. The software created and designed by our specialists, allows simple visualisation of the production flow, data analysis and the creation of reports according to the needs of the company. The entire process is created in line with Industry 4.0.

The insight into the data from the production machines also allows for fast and efficient diagnostics. Intelligent machines, thanks to their sensors, can themselves signal the need to replace a component or carry out an inspection.

Data analysis and presentation

An important feature of the fourth industrial revolution, which has significantly changed the face of manufacturing, is the ability to use production data from different machines. This makes it possible to optimise production processes. From the point of view of data utilisation, the form of data presentation is also crucial.

Our software allows the creation of reports configured to the needs of the company. Reports can be supplemented with additional charts and tables to extract the most important information. Reports can include information on the productivity and occupancy of individual machines, as well as information on stock levels, the automated storage system.

How is the fourth industrial revolution different from the third?

Automation, which is much talked about today, has played an important role in industry for several decades. The previous, third industrial revolution, also known as Industry 3.0, also involves machine automation and control using software. However, it is worth highlighting some important differences between the third and fourth industrial revolutions.

The automation of industrial processes in the third industrial revolution was based on programmable logic controllers (PLCs) or computer numerical control (CNC) machines. These technologies provide computerised control of machines and enable communication between them. However, they do not include the kind of extensive digital layer that Industry 4.0 encompasses. The previous era in industry is also not about using data to optimise production. Advanced but easy-to-use software enables complete data analysis and provides a simple and clear presentation that makes it easy to monitor the performance of individual machines and production as a whole.

How do we at Baumalog help companies introduce Industry 4.0 solutions?

Our systems fit into the ideas of Industry 4.0, supporting companies on their journey to thrive in the digital revolution. Each of our solutions combines the physical functionality of machines with a virtual space, enabling simple, fast and efficient operation. Here are some examples of how we are implementing Industry 4.0 solutions.

Automation of laser cuttting machines – machine integration and Industry 4.0

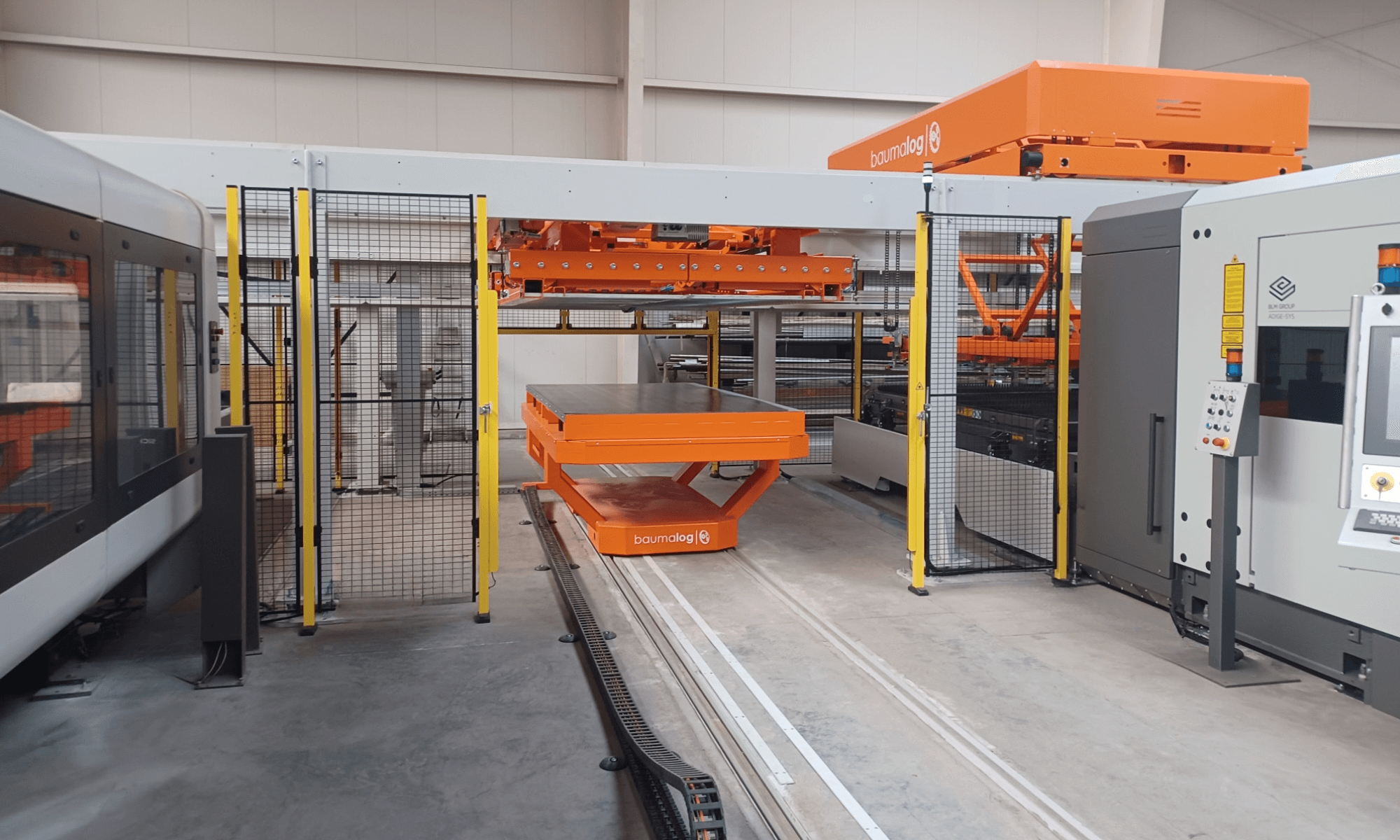

The SmartFlow System is our flagship product for the efficient flow of sheet metal to the laser. All components of the entire process are:

- Automated storage process

- Material flow from the storage system to the transport system (MultiLoader)

- Automated loading and unloading of the laser cutting machine

- Return of cut parts to the automated storage system or delivery to the sorting area

A key aspect of the SmartFlow System is the integration with the laser cutting. Our systems can integrate with laser cutting machines from almost any manufacturer without compromising the quality of the overall process. With machine-to-machine communication throughout the system, production downtime can be eliminated and laser cutting can be fully utilised.

Check out the full range of automated systems from Baumalog: Automation Systems from Baumalog

Automated storage – a significant simplification of the process

The storage of material – sheet metal, long items, heavy items and large tools – is a challenge that can also be optimised with modern solutions. The storage systems we manufacture as standard have software that enables comprehensive storage management.

The key benefits of Baumalog automated storage systems are:

- Storage space savings of up to 90 per cent.

- Increase in the efficiency of material flow within the system

- Real-time monitoring of stock levels

- Increased safety of work

- Ease of operation from the control panel

To find out more about our storage systems, visit our offer page: Baumalog Storage Technology

What is Industry 4.0 for your company?

Industry 4.0 solutions are becoming increasingly popular in many industries, especially in the areas of manufacturing, logistics, transport or urban economy. Innovative solutions in automated systems represent an opportunity to streamline many processes within a company. In the area of production and storage, machines that integrate and communicate with each other can enable full capacity utilisation. Using the laser cutting machine as an example, automated systems are able to increase cutting times by up to 90%, minimising the idle time of the laser cutting machine, also allowing the machine park to operate at night or at weekends without the need for operator supervision. Autonomisation of processes is nowadays within reach. It is worth taking advantage of the opportunity to streamline production processes and build a competitive advantage by increasing productivity and optimising key company processes.